In aerospace, MRO (maintenance, repair, and overhaul) is expensive and time-consuming for the commercial aerospace industry, but there are new ways to reduce repair costs and downtime while maintaining safety and durability. VRC Metal Systems’ high-pressure cold spray adds fresh, solid metal without melting anything. It can be used to repair and enhance parts, decreasing the need for parts replacement.

Aircraft sheet metal repairs using high-pressure cold spray provide substantial savings and quick ROI. Aluminum panels with temperature-sensitive stiffeners have been repaired, with cost and turnaround time being an order of magnitude lower than replacement. Repairs on sheet metal that remained in place on the aircraft also demonstrated these time and cost savings.

Thus, VRC’s high-pressure cold spray is a solution for manufacturers and operators to repair damaged aircraft and sheet metal components, sometimes without removing them. Compared with traditional structural repair methods, cold spray produces equal or superior results in strength, durability, and corrosion resistance.

VRC Metal Systems’ high-pressure cold spray equipment and processes are suitable for use in many industries, including aerospace, maritime, oil and gas, nuclear, and automotive. Using these processes, you can add metals where desired, such as in worn and corroded areas.

If desired, you can blend in ceramic particles for added wear resistance. You can enhance parts by adding a coating with higher corrosion and wear resistance than the base material. HPCS coatings are metallurgically bonded and have high strengths, sometimes matching wrought specifications of the deposited material.

Contact us to learn more about our cold spray technology, equipment, resources, and services.

Sheet Metal in Aircraft Design

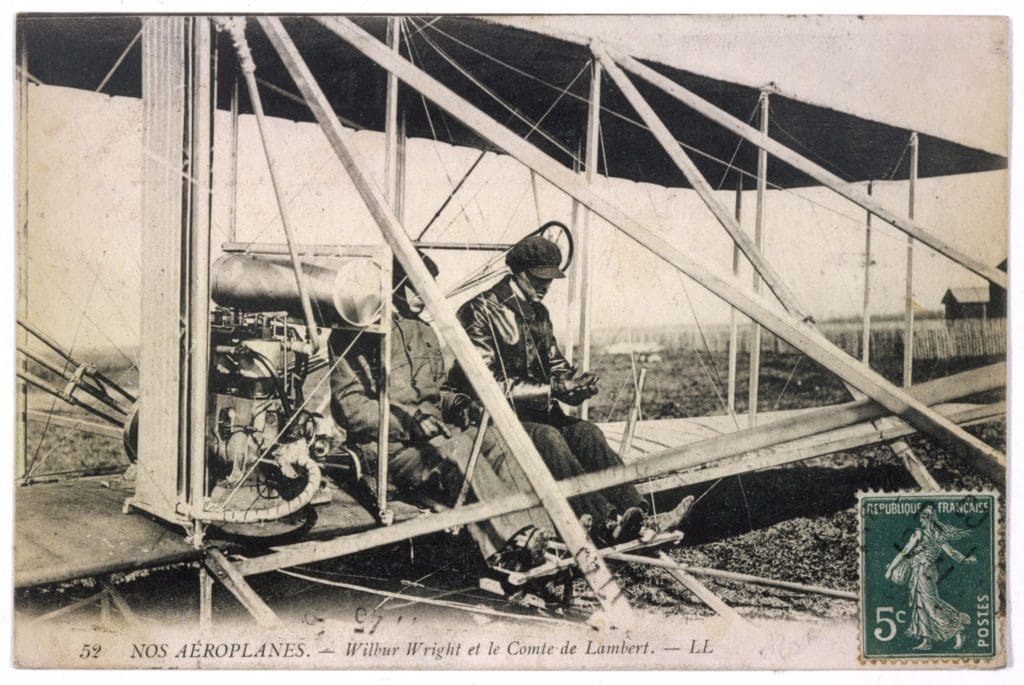

In 1903, the Wright brothers successfully flew their first power-driven aircraft made from wood and fabric. Before World War II, most single-engine aircraft were still made from wood-framed fuselages and wings covered in fabric. World War II saw the first use of metal aircraft. Sheet metal and composites make up the bulk of today’s aircraft structures.

While accounting for a majority of the aircraft structure, sheet metal components are assumed to have a finite life expectancy. Therefore, they typically require replacement due to wear and tear from accidents, corrosion, and other stresses. In addition, unexpected corrosion and wear can require unscheduled maintenance and unplanned replacements, which are costly and reduce aircraft availability.

Different Types of Stresses

The following are some of the more common stresses sheet metal components experience:

- Mechanical – This type of stress occurs when a force is applied to an element, tearing or stretching the metal.

- Thermal – Temperature changes cause thermal stress, which results in the metal expanding and contracting. This type of stress is especially problematic in aircraft design as these vehicles operate in all kinds of climate conditions with rapidly changing temperatures.

- Fatigue – The repeated application of a force on a structural element causes this type of stress. It can lead to cracks in the metal which can grow over time until the part fails.

Material Loss Mechanisms

- Chemical – Corrosive aircraft chemicals used for de-icing, antifogging, and other purposes can cause corrosion, weakening the metal. This type of deterioration is one of the reasons why some aircraft components have turned to materials such as fiberglass or corrosion-resistant lightweight metals.

- Abrasion – Aircraft skins and components may suffer abrasion from airborne sand, dust, or even volcanic ash. Abrasive wear quickly sets in if these become trapped in lubricants between mating surfaces.

- Adhesive wear occurs when components are in dry contact, such as between fasteners (bolts) and removable panels.

Benefits of VRC Cold Spray Repair

VRC Cold Spray has several advantages over traditional methods:

- Corrosion Resistance – Cold spray technology is a quick and efficient way to apply corrosion-resistant materials. These include unalloyed aluminum for high corrosion resistance, Al6061 where a combination of good strength and corrosion resistance is desired, Grade 1 and Grade 5 titanium, nickel and nickel-based superalloys, and many others. Due to the rapid application process, there is also no time for particle oxidation, preventing corrosive pockets from developing between the coating and substrate as well.

- Strength and Durability – VRC Cold Spray also produces superior strength and durability results than traditional repair and coating methods. Because the materials are deposited in a solid state, they possess the highest strengths of any thermal spray process.

- Ease of Use – The portability of the VRC Cold Spray systems means the damaged or fatigued component may be able to stay in place during the repair process. No unassembling, transporting, or re-assembling is required.

- Cost-Efficient – time is money, as the saying goes, so the quick repairs afforded by cold spray technology can reduce your labor budget and downtime. In addition, repairing or extending the service life of components instead of replacing them will also save on expenses in the long run.

Enhanced Aircraft Sheet Metal Construction and Repair

Cold spray technology offers corrosion resistance, increased structural integrity, and superior coating strength that other repair methods cannot match. The portability of the VRC Metal Systems makes it an ideal format for working with larger structures such as aircraft panels.

When you decide it would be more cost-effective to repair those large components in place rather than transport them to a repair facility or replace them entirely, reach out to us at VRC Metal Systems. We have the solutions, materials, and expertise to bring your MRO budget into line.