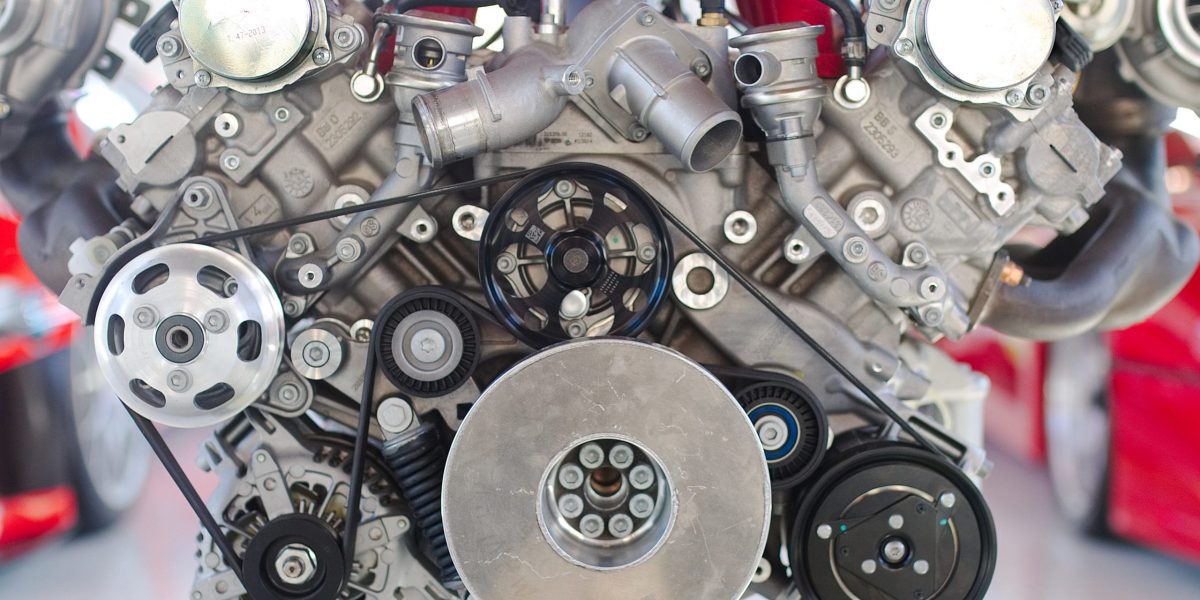

Engine Remanufacturing Cold Spray Solutions

Approximately 4,000 machine shops in North America remanufacture about 1.5 million engines annually by machining core parts back to OEM specifications.

With increased competition and other cost pressures, vehicle fleet operators look to keep their current assets running longer. Supply chain disruptions have caused several shutdowns at vehicle manufacturers, and new engines have been in short supply. New engines are also very expensive compared to remanufactured ones, meaning that engine rebuilding continues to be a viable market. Cold spray technology has proven to be an effective solution for rebuilding engines.

Engine Remanufacturing Industry Challenges

Challenges within this industry come from:

- Pressure to reduce the carbon footprint of new manufacturing

- Growing EPA regulations raising the cost of maintaining new engines

- Increased demand from price-driven consumers with older equipment

- Increased use of remanufactured transmissions in electric/hybrid vehicles

Within the engine remanufacturing operations itself, though, lie challenges with inaccurate inventory forecasting, excess or unavailable inventory, and supply chain bottlenecks. Unpredictable and long processing and wait times are denotable operational challenges as well.

VRC’s Solution for the Engine Remanufacturing Industry

Cold spray technology can repair or improve what already exists, eliminating the need for new components and alleviating the dependence on fluctuating inventory supplies. In other words, components that were unrepairable by other means may be salvaged by cold spray.

For example, cold spray cast iron repairs don’t require any preheating of the part, saving energy and labor cost. Cold spray is solid state and unaffected by gravity so that repairs can be done in any orientation, even straight up. You can repair aluminum castings with minimal prep and repair time.

VRC Metal Systems’ cold spray technology and equipment are cost-efficient, repeatable, and reliable resources with the following added benefits.

- Cold spray repair systems are portable, potentially streamlining procedures by eliminating time-consuming inventory transfer steps between work centers.

- This low-temp process produces no heat-affected zones, thereby eliminating warping and loss of temper.

- Aluminum castings and stampings benefit from this. They are often uneconomical or infeasible to repair by other means.

- Engine blocks do not require preheating, and since the process itself is low-temp, there is no cooldown phase, which ultimately eliminates time from the repair process on both ends.

- The focused particle spray path reduces the need for masking, again eliminating a time-consuming setup step.

- Maintaining minimum wall thickness is possible through multiple repair cycles, as you can use cold spray to repair cold spray coatings.

- Metallurgical bonding achieved through this supersonic particle deposition process can strengthen the base material.

- Metal, metal alloy, and composite coatings can all be applied, creating surfaces that are more resistant to corrosion and wear.

- Cold spray applies high-strength, high-density coatings, machinable with conventional subtractive manufacturing methods.

- Minimal surface prep is needed eliminating additional setup steps and the hazardous air particulates of other repair methods.

VRC Metal Systems is trusted by government organizations and reputable institutions worldwide. With VRC’s High-Pressure Cold Spray systems, you receive expert on-site implementation and maintenance support from highly-trained staff.

If you’re interested in a cost-effective solutions for your engine remanufacturing, request a quote, and one of our Sales Engineers will contact you.

Contact VRC Metal Systems today to find out how cold spray technologies can support your building repair and maintenance needs.

our Services

ON-SITE SUPPORT

We provide on-site support for all our services as standard

SYSTEM CALIBRATION

Products can be configured by one of our experienced technicians.

EQUIPMENT LEASE

We offer a variety of equipment lease options for you and your company.

Our trained engineers across the nation offer short & long term solutions for your aircrafts

COLD SPRAY PRODUCTS

Check out all our best selling cold spray products here!

ARTICLES

Read More!