When metal repairs must be performed swiftly in environments where large machinery may not be feasible, a reliable and portable...

Read MoreBlog

Cold Spray vs Thermal Spray – An Overview

What do the aerospace, shipping, oil, gas, and mining industries all have in common? They have high-dollar components that cause...

Read MoreMid-America Aerotech Completes IP Purchase from Moog, Inc

Mid-America Aerotech, LLC, a leading provider of aircraft repair and maintenance services, announced today that it has completed the IP...

Read MoreU.S. Navy partners with VRC Metal Systems for Fleet Repair

SAN DIEGO, Calif. (USNI News) – If a part breaks on a ship or submarine sailing in a conflict zone...

Read MoreSenator Rounds tours VRC Metal Systems

Published: Sep. 4, 2023 RAPID CITY, S.D. (KOTA) – With the unit of B21 bombers scheduled to arrive at Ellsworth...

Read MoreVRC Metal Systems Receives Lockheed Martin Small Business Award

Box Elder, SD (July 1st, 2023) – VRC Metal Systems, a leading developer of advanced cold spray technologies, announced that...

Read MoreBOSS Magazine: Supersonic Superpowers

VRC Metal Systems was recently featured in BOSS Magazine, not only showcasing our premier cold spray services but also our...

Read MoreHow VRC Metal Systems Is Changing The Game On Repairing Metal

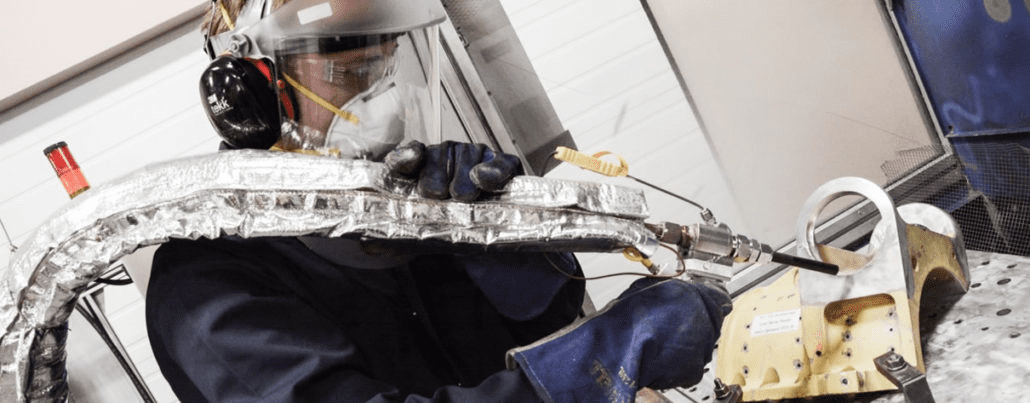

VRC Metal systems produce a cold spray, better known as supersonic particle deposition. It is a high-energy solid-state coating powder...

Read MoreIntroducing The C.A.M.P. Site™ System

View Full Video For Entire Walk-Around Of The C.A.M.P Site™ System Introducing the VRC Metal Systems C.A.M.P Site™ Cold Spray...

Read More