When it comes to undertaking repairs, there are a few essentials to consider: materials, reliability, and the best method to get to the desired outcome.

Cold spray is an increasingly popular technique within a wide range of industries and has become commonly used in repairs. Many business types are making the most of this technology, and it has earned its place in a variety of uses.

Here at VRC Metal Systems, we are skilled in the application of cold spray technology and have been using it for the past seven years to help businesses boost their productivity.

If you are involved in the metal industrial repair business, read on to see how it could help you. Whether your role is performing maintenance in the energy sector, breathing new life into ships and airplanes, or manufacturing metal components, you could benefit!

Staying up to date with industrial advances is crucial; it keeps you at the front of the pack in your industry and ensures that your business is running in the most efficient, up-to-date manner possible. Plus, it will keep your team excited about their jobs and invigorated by seeing the impossible become possible!

Read on to see who is taking advantage of cold spray technology, and why joining them could be the best decision you ever made. Then give us a call at VRC Metal Systems for all your cold spray product and service needs.

What Is Cold Spray Technology?

Cold spray technology is a technique first observed in the 1980s at the Institute of Theoretical and Applied Mechanics of the Russian Academy of Sciences. It was then brought to the U.S. in the mid-90s where research and development began by high tech entities like Sandia National Laboratories and the Army Research Laboratory. Since that time, it has seen tremendous growth and become a staple of many industries.

Cold spray is one of many names used to describe a solid-state coating process. A high-speed gas jet is used to help accelerate powder particles toward a substrate, which can be metallic or nonmetallic. Upon impact, the particles plastically deform and consolidate, adhering the metal powder to the substrate.

The term ‘cold spray’ is due to the low processing temperature. Unlike typical metal working processes, the spray temperature is usually far lower than the melting point of the spray material.

Cold spray technology is, therefore, suitable for depositing a vast array of advanced and traditional materials onto a wide range of substrate material types. It can be especially useful in non-traditional applications which are temperature-sensitive during the process, such as heat-treatable alloys, nanomaterials and amorphous materials.

What Are The Advantages?

The popularity of cold spray is not without good reason. The technology offers a host of advantages to manufacturers, including:

- Using a low-temperature process compared to other techniques – this has the bonus of no bulk particle or substrate melting

- Minimal oxidation during the process

- Maintaining minimum wall thickness requirements through multiple repair cycles

- Allowing you to retain composition/phases of the initial particles

- Reducing or eliminating solidification stresses while enabling thicker coatings to be created

- Providing low defect coatings

- Ensuring high hardness thanks to a cold-worked microstructure

- Requiring minimal cut-back of base material

- Reducing cooling requirements at the other end due to the lower temperature

- Reducing or eliminating grit blasting requirements for substrate adhesion

- Allowing parts to be repaired multiple times during the life cycle of the base material

- Producing a better surface finish

- Eliminating distortion

Who Is Using Cold Spray Technology?

As we discussed, cold spray technology is now becoming increasingly popular in a wide range of industries. Some of the uses include:

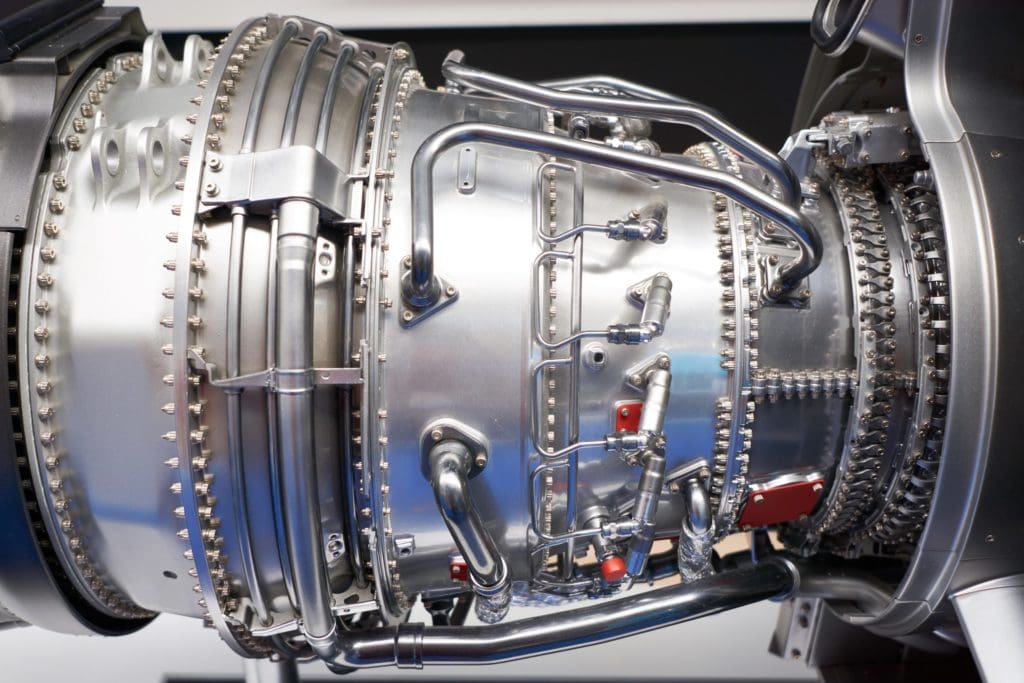

Aerospace Component Repair

As you can imagine, when it comes to repairing aircraft, there is no room for error. Cold spray technology is particularly popular here due to its ability to repair heat-sensitive metals. Aerospace materials are not cheap, and repairs are far more economical for businesses – not to mention ticking the box for staying green.

Aircraft Skin Repairs and Access Panel Repairs

The skin of an aircraft is required by industry standards to be a certain thickness. Cold spray is one of the only technologies available which allows repairs to maintain this without compromising the integrity of the repair.

In addition, many of the alloys used in the aviation industry exhibit high levels of sensitivity to elevated temperatures. Titanium, aluminum, and magnesium are the most common alloys used – all sensitive to oxidation and the effects of heating and cooling material quickly.

The lower temperatures required for the process, therefore, make it a perfect fit for aerospace engineering. There is no need to cool down afterward, and the initial temperatures are not high enough to cause the alloy to weaken.

Liquid Handling System Repairs

If you are involved in the repair of machinery and pipelines handling liquids, cold spray could also help. Active pipeline leak repairs are possible with this technology, as well as repairs to energized systems, whether they are tanks, fittings, pipes, or valves.

The low working temperatures required by cold spray allow the structural integrity of the substrate to remain intact. This feature means that in the case of corrosion or damage to a pipe, you can make the repair without causing further weakness or damage to the strength – a feature that is critical if you are working on an active pipeline. It also allows the targeting of repairs to the affected area, unlike welding, which requires a total overhaul of the pipe or system.

In addition, the application of cold spray deposits can enhance a substrate over time and repeated application. Ceramics and carbides can be incorporated, and this helps to provide significant wear benefits, at percentage additions as low as 20%.

Depending on your requirements, you can deposit materials with different electrochemical corrosion potentials. The cold spray zone may corrode preferentially (anodic), at a similar rate to the substrate (matching), or be protected from corrosion (cathodic). You can also add coatings to resist chemical corrosion for extended longevity.

Cold spray allows for hard to remove components in a system to be repaired, rather than replaced, without concerns for their long-term structural integrity or strength. Other methods would require stripping, dismantling, and replacing the part.

Those other existing repair actions extend the length of the project and cause a significant inconvenience. Repairing the component, in situ, and to a higher standard is the “holy grail” for these customers and is a significant factor in why the process is gaining popularity.

Large Equipment Repairs

Cold spray technology can also be invaluable when it comes to large equipment repairs. Invaluable, mainly for the reasons we mentioned earlier — it allows for dedicated, targeted repair to the area of damage, as opposed to requiring entire components to be removed and replaced.

Discover the benefits of cold spray with VRC Metal Systems

Here at VRC Metal Systems, we have the skills and the tools needed to transform your metal repair processes. We have plenty of experience in the world of cold spray technology and can use it to help streamline your repairs, boost productivity, and allow your business to benefit. Get in touch with us today to learn more about the cold spray products and services we offer.