View Full Video For Entire Walk-Around Of The C.A.M.P Site™ System

Introducing the VRC Metal Systems C.A.M.P Site™ Cold Spray System. C.A.M.P Site™ stands for Cold Spray Advanced Manufacturing Portable Site which means this containerized unit is our most powerful and relatively portable unit to date.

The C.A.M.P Site™ system is designed to be self-supporting for all operations without additional additives besides a water connection for the dust collector part of the unit.

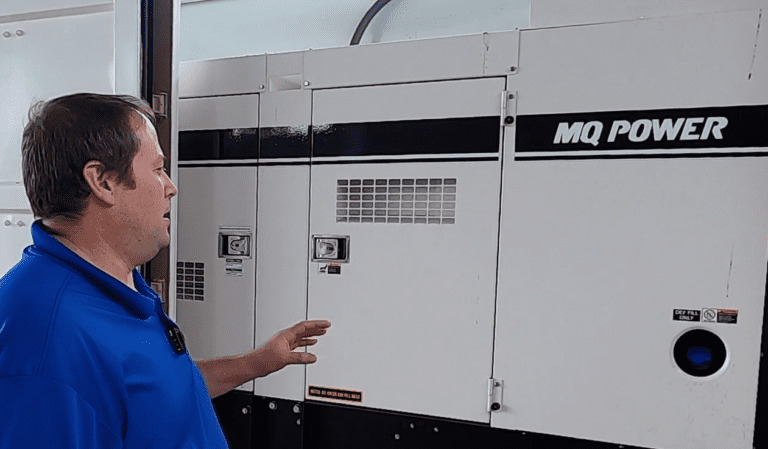

The system starts off with a generator that supports the entire unit’s power requirements. This generator has a 125kVA output capacity that is produced by an Isuzu water-cooled, direct injection, turbo-charged diesel engine providing a 3-phase 480VAC power supply while also being tier-4 final emissions compliant.

The unit utilizes a “PowerBalance” system to maintain sufficient load on the engine for low-load scenarios to preserve the expensive and intricate pollution control equipment. This generator supplies 110 Amps to power the cold spray system, compressor, the dust collector, robotic system and all the lights & electrical equipment inside the Site itself. Additionally, the generator was designed for quiet operation with a measured median of 74dB(A) at the control panel.

The other major key factor for the C.A.M.P Site™ being self-supporting is the compressor system that supplies a working pressure of 4500psi. Behind the compressor itself there are 24 bottles (two 12 packs) of compressed gas, each capable of 4500psi. This gives the unit enough gas on hand, depending on the recipe being used, to spray continuously for up to 8 hours.

The compressor itself is a 4-stage, air-cooled, oil lubricated system with large stainless steel cooling tubes with equally large condensate separators. The compressor has a charge rate of 24.6 standard cubic feet per minute powered by a 20HP 3-phase motor. The compressor gives us enough pressurized gas to accomplish any and all cold spray operations.

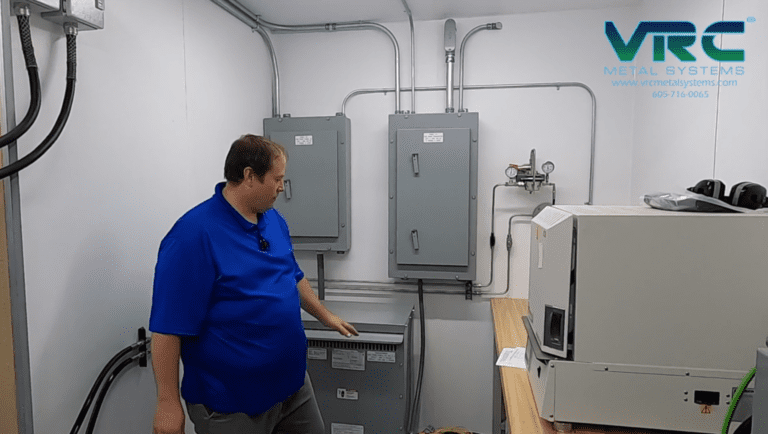

Directly behind the compressor and the generator on the inside sits the remainder of the utility cell.

Inside this room is a dome regulator for the gas coming into the system from the compressor along with a distribution panel and transformer. There is also a work bench with a tool box with every tool you could possibly need for the system. Additionally, there is an Heater/AC unit that maintains the working environment for the operator’s sake along with a small laboratory furnace capable of temperatures of to 1200°C that can be used for PBI nozzle drying, powder drying, powder processing and adhesion test glue setting.

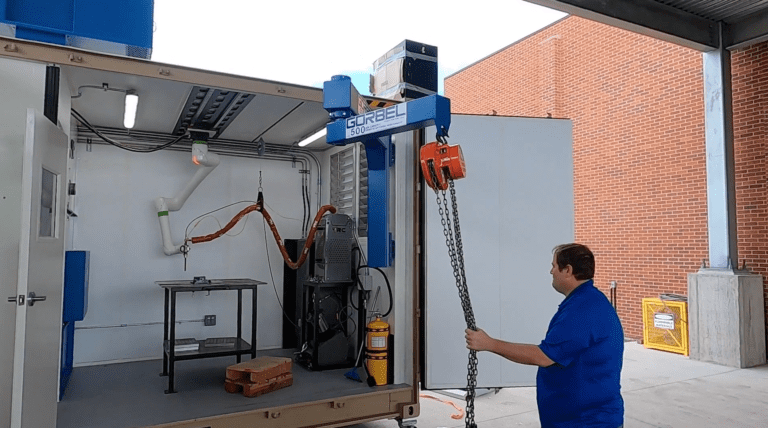

Directly next to the utility cell room is the cold spray cell. The two rooms/cells are protected by a weather tight seal to keep all elements out.

In the booth there is a dust collector that pulls in 5500 cfm to ensure all fugitive dust is collected during operations. There is a fixture table ready to be sprayed on, the gas train for the VRC ® RaptorTM Cold Spray System and the powder feeder with the heater directly above. Additionally, there is a jib crane/hoist that is able to extend out the bi-fold doors to the outside to bring in any larger parts into the spray booth up to 500 lbs. The fixture table is moveable while the powder feeder and heater can be moved but their stands are fixed, giving you the opportunity to adjust the tools to meet your needs.

All of the operations that occur within the spray booth are aided by the CRX10 Fanuc 6-axis arm robot that sits along a roof’s linear rail system for mobility. The last feature of the spray booth is a pass-through door that allows you to perform hand spray operations outside the booth by taking the heater and powder feeder outside the cell and feeding the gas and power lines outside to the heater and powder feeder. This feature gives you even more capability when it comes to cold spray repairs.

The entire C.A.M.P Site™ is able to be moved just as a shipping container does while housing all of the advanced cold spray technologies from VRC Metal Systems. The entire system is self-supporting while also providing every possible tool you could need for your cold spray repairs. The C.A.M.P Site™ system is VRC Metal Systems latest and greatest development of cold spray technology and solutions for the rapidly growing industry.

If you or your business are interested in the C.A.M.P Site™ system or any other products or services from VRC Metal Systems, contact us today. Our team is ready to help you learn, adapt and utilize cold spray solutions for whatever your needs may be. Contact us today here or give us a call at 605-716-0065