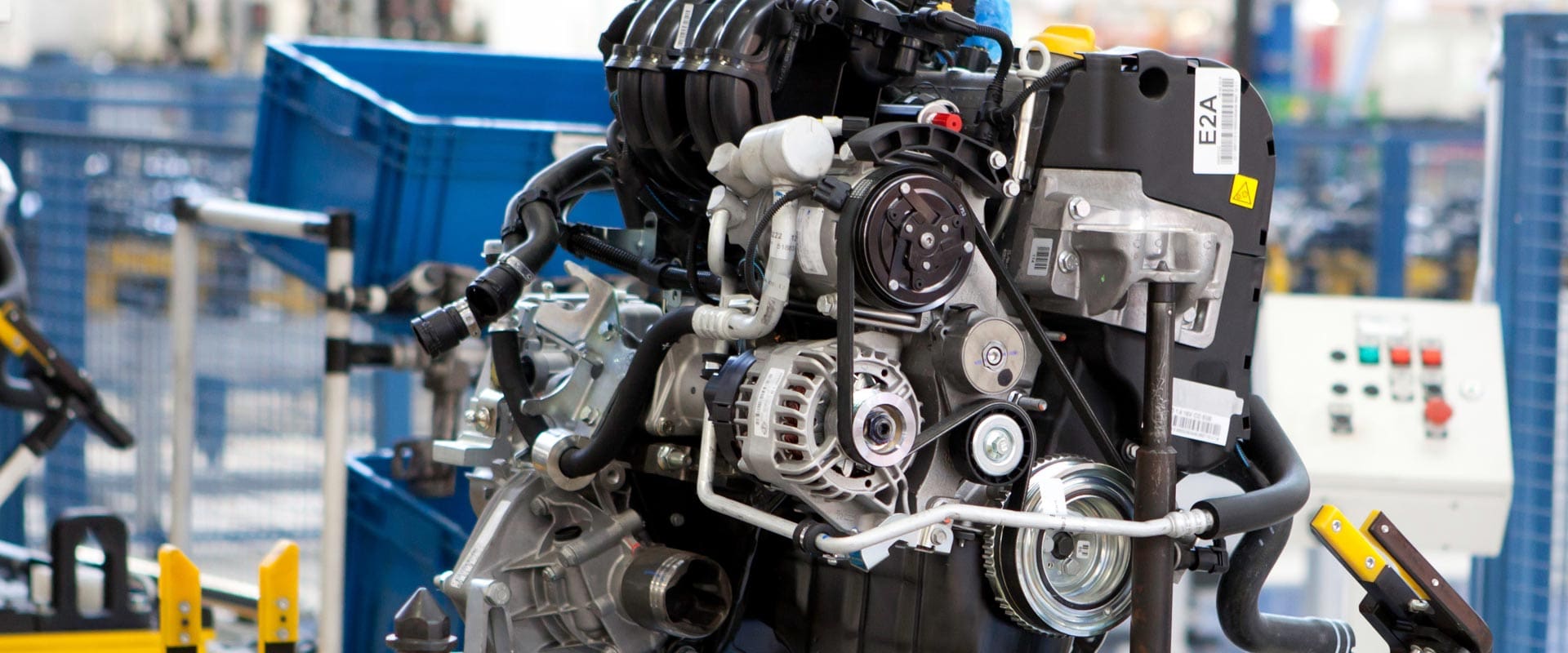

Engine Remanufacturing

Our mission statement is, “Provide innovative, reliable metals deposition and automation technologies and manufactured components to give our customers market-leading capabilities.“

Finding new strategies and new technologies to handle age-old problems is our specialty.

Historically, when an engine goes bad it is often unrepairable or simply too costly to repair. A corroded cylinder edge can be the end of an engine if you don’t have the technology that allows you to fix it economically. Conventional repair of cast iron entails energy- and time-consuming preheating (along with careful cooldown), while aluminum easily warps beyond repair when heated by welding or other melt- based processes.

Our cold spray technology is changing the face of engine repair, making it an affordable option when nothing else seems to be going your way. It is solid state, requires no pre-heating of cast iron or other metal components, and heat inputs are very low. You only deposit the material that is needed, and you can deposit stronger, more corrosion-resistant, and more wear-resistant material than the base material.

Challenges of Engine Remanufacturing

New vehicles have had to change their engines for better emission control and improved efficiency. The Environmental Protection Agency has tightened up its requirements for better management of emissions. Some of these new designs, although efficient, may not allow for traditional repairs. And if you can repair it, you may not be able to afford it. At the same time, fleets are seeking to keep their current equipment running longer, making repair and remanufacturing attractive options.

Difficult repair jobs can require an extensive process that may involve heating the entire block to extreme temperatures and cooling slowly over several days to prevent metal damage caused by temperature variance.

Remanufacturing engines can thus be cost-prohibitive using traditional techniques. The remanufacturing complexity can limit the options for smaller operations. Additive manufacturing and remanufacturing had opened the door to a longer lifespan of engines where before the doors were firmly closed.

How VRC Can Help with Engine Remanufacturing

VRC’s cold spray technology does not require extreme heat in the remanufacturing example. There is no significant wait time for the engine block to cool. Wait time adds cost to the product, but trimming wait time improves your return on investment.

Cold spray can replace costly and complex procedures with its portable and innovative system. Often the process can be done in place without extensive engine disassembly. Some repairs are even possible without removing the engine from the vehicle!

Engine remanufacturing using this innovative technique has made established methods seem archaic. VRC can help you decide what technique is best for you.

our Services

ON-SITE SUPPORT

We provide on-site support for all our services as standard

SYSTEM CALIBRATION

Products can be configured by one of our experienced technicians.

EQUIPMENT LEASE

We offer a variety of equipment lease options for you and your company.

Our trained engineers across the nation offer short & long term solutions for your aircrafts

COLD SPRAY PRODUCTS

Check out all our best selling cold spray products here!

ARTICLES

Read More!