Military vehicles are under constant attack from an unexpected enemy – corrosion.

Corrosion damage to military ground vehicles cost the US Army 1.2 billion dollars in 2016 alone. There is a huge cost to keeping military vehicles in ready repair. When considering how cold spray might help military vehicle repair, you can easily point out a few primary benefits.

VRC is a leader in cold spray innovation with proven performance across demanding industries. This technology can help you outperform and outlast your competition. Contact VRC Metal Systems today to explore how cold spray will keep your vehicles moving.

Three key factors that cold spray provides to benefit our military are:

- Huge cost savings

- Environmentally friendly application

- Enhanced protection for military equipment

Before we get any further, let’s summarize cold spray:

The Cold Spray process is a low-cost, low-impact repair option. It can add significantly more material to a surface than traditional electroplating. This technology can repair issues without the distortion caused by welding or the creation of heat-affected zones. It can be used to create combinations of materials that are difficult or impossible to make by other means.

Cold spray is used for a wide variety of applications.

These uses range from aerospace to shipyards or pipelines to manufacturing processes. Cold spray is a reliable solution for many repair and surface protection needs. It is often used as a reliable anti-corrosion solution.

So, let’s break down the benefits of cold spray for military vehicle repair.

Cold spray repairs act as force multipliers by increasing asset availability.

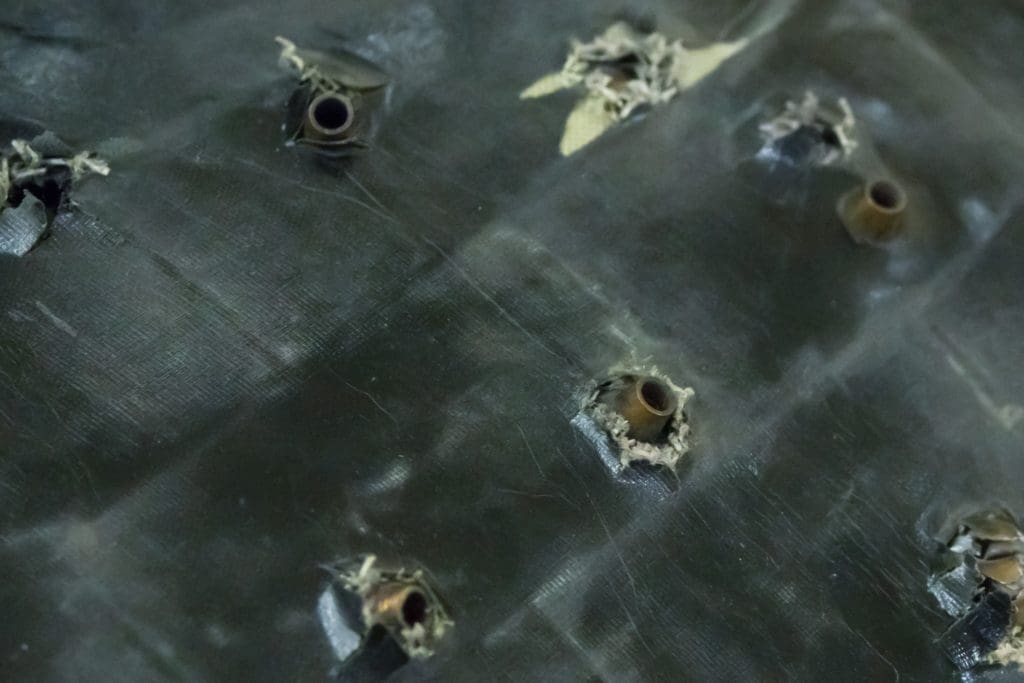

A prime example is the B1-B aircraft, which has eight Forward Equipment Bay (FEB) panels that are removed for equipment inspection before and after each flight. These panels are made of high-strength aluminum and have complex composite stiffeners that increase the rigidity of the panels while keeping their weight low. Over time the fastener holes become worn beyond specification, but because of the temperature sensitivity of the composite stiffeners the holes cannot be repaired by weld overlay or any other melt-based process. The lead times for replacement panels were up to 18 months. Cold spray provided the solution, and panels can be repaired in a matter of weeks, including prep time and post-repair inspections.

Cold spray repairs can save our military millions of dollars.

Ensuring that defense vehicles are in full working order and ready for action is imperative and also expensive. New repair innovations can help our troops repair their equipment in less time while also reducing overall cost.

Cold spray technology from VRC saves you time and money.

Traditional repair timelines keep equipment out of use for weeks or even months on end. Many US Military repair depots are overwhelmed. Important equipment is left to rust as technicians try to catch up with the repair demand. Corrosion repair used to require dangerous and tedious part removal and overhaul. Preheating is not required for cold spray repairs, even when repairing cast iron.

Repairs are possible on-site in a matter of minutes.

Cold spray is the option that you have been waiting for. With its ability to be utilized in-situ, cold spray equipment is portable and easy to use.

The US military spends millions of dollars on corrosion repair each year.

We want our armed forces to be operating as efficiently and safely as possible. Unfortunately, many military vehicles are made of high-hardness steel that is very susceptible to corrosion.

Protect your metal surfaces with cold spray.

Even minor corrosion damage can degrade an army vehicle’s protection rating and put it outside the allowable tolerances. Metal parts and metal surfaces need corrosion-resistant coatings to last a lifetime. Galvanically neutral coatings can be deposited, or if desired, more noble or more sacrificial coatings can also be deposited.

The cost or repair versus replacement:

Cold spray repair deposits an enhanced surface finish without the need for new parts or a complete overhaul. Instead of spending millions on components or vehicles, you can put cold spray to work to replenish damaged fleets. Cold spray technology enhances the lifespan of your high-value assets. It improves your metal surfaces with an anti-corrosion layer.

Second, cold spray is a “green” solution for military vehicle repair.

Cold spray provides a tremendous opportunity to minimize your manufacturing footprint.

Your metal surfaces will last longer with cold spray repair. You will no longer need to feed a seemingly endless waste cycle. Elongating the lifespan of components and military vehicles will decrease the overall environmental footprint, saving money and our planet.

There are no toxic fumes when dealing with cold spray.

You might have experienced smoke or fume inhalation when using traditional methods of metal repair. With cold spray, you do not need to worry about solvent or molten metal fumes. This innovative process only uses inert gases, such as nitrogen and helium, keeping you and your planet safe.

Waste powder from cold spray is easy to collect and dispose of.

Similar to powder that results from grinding metal, cold spray leaves waste powder residue on nearby surfaces. This powder can be easily collected and disposed of in accordance with Federal, State, and Local regulations.

Lastly, cold spray provides enhanced protection.

VRC Cold Spray systems can provide enhanced protection with cold spray metal surface repair.

Many materials are compatible with cold spray technology.

Pure metals, alloys, and even non-metallic particles can be deposited via high velocity as a surface coating. Depending on the demands of your environment, you can customize your cold spray finish. Anti-corrosion properties can be added to create a durable and long-lasting metal coating. Blends of metals and ceramics can be deposited to create a highly wear-resistant surface.

Different materials mean different protective capabilities.

Cold spray repair can restore and even increase the maximum ballistic resistance of corrosion-damaged armor panels. You can add various metals with enhanced strength and corrosion resistance characteristics to the cold spray powder. Your new layer can be built up stronger than before damage ever occurred. VRC Metal Systems technicians are experts in military vehicle repair.

Military equipment experiences harsh environments.

Saltwater, high humidity, dust, dirt, and heat will begin to affect your vehicle’s metal surfaces negatively. Without proper maintenance and repair, expensive assets are rendered useless or dubbed unfit for military use.

Adding a protective finish with cold spray will increase the lifetime of your assets.

Cold spray will leave you with less maintenance to worry about in the long run. You can utilize this technology as a protective coating to fight against signs of corrosion.

Cold spray is at the forefront of a repair revolution.

After years of innovation and experimentation, VRC Metal Systems is excited to offer the benefits of cold spray to you. With huge cost savings, enhanced protection, and environmental benefits, what’s not to love?

Cold spray technology is an exciting and promising solution to your traditional corrosion and surface repair challenges. Contact VRC Metal Systems today to explore how cold spray will keep your vehicles moving.