Metal deposition describes any additive manufacturing method where a metal is layered onto some other material such as metals, ceramics, and even plastics. How the metal is deposited onto the substrate can vary greatly. Today, we will take a look at a few different types of metal deposition – and, of course, why we think cold spray (specifically OUR VRC cold spray) is the best!

VRC Metal Systems and their cold spray technology have made additive manufacturing through metal deposition quick and easy for your manufacturing or repair team. Contact us today for training and a quote.

Different Types Of Metal Deposition

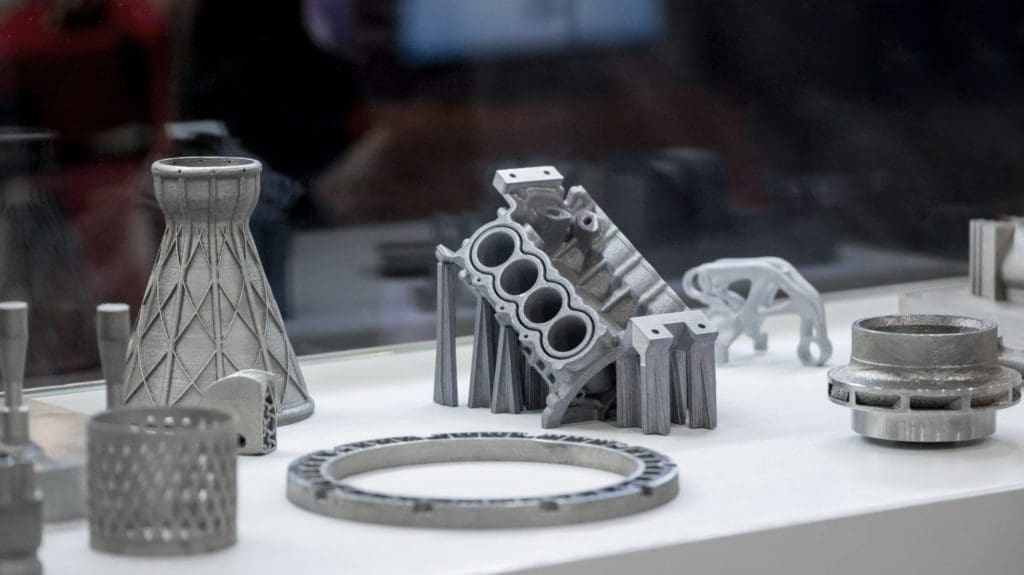

There are many types of metal deposition; we will briefly discuss three of them: Layer metal deposition, direct metal deposition, and cold spray deposition. Each offers a unique technique to the manufacturing process.

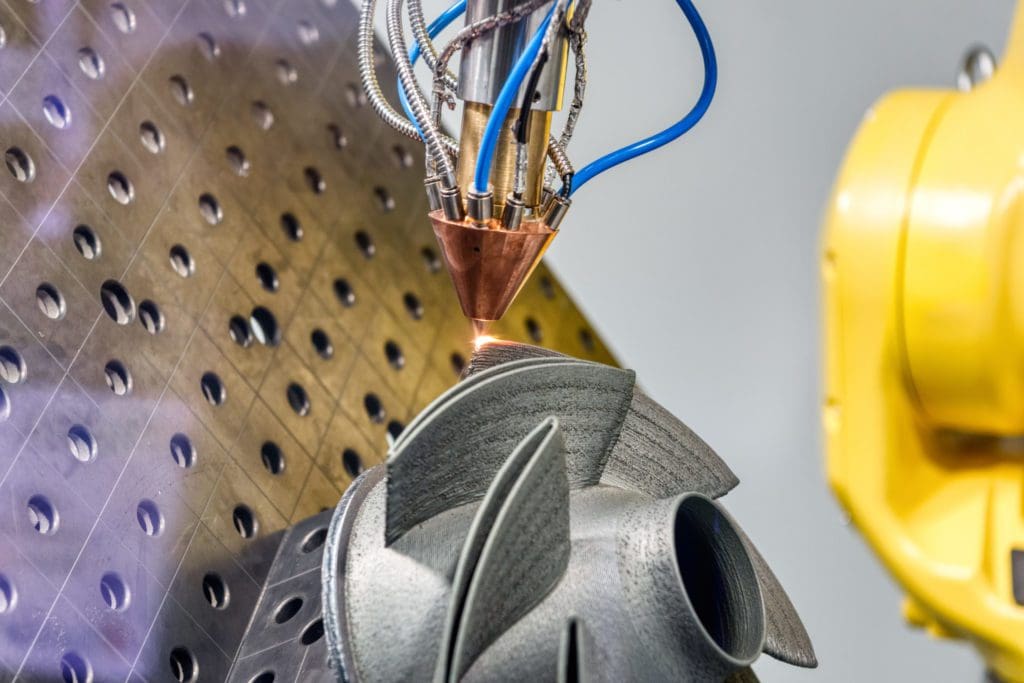

Laser Metal Deposition

Laser metal deposition (LMD) is an additive manufacturing (AM) technique that uses a powerful laser beam (equivalent to a thousand laser pointers) to melt metal powder that is fed into the path of the laser light. The powder is fed with a gas stream (typically argon) and this gas stream moves the melted particles along. The molten metal droplets solidify when they hit the base plate and build on each other. The base plate can be moved around so that the melted metal droplets build specific shapes, much like some plastic 3D printers work. Multiple layers build up one by one to create the three-dimensional component. Because of this layering, technicians can produce high-dimensional accuracy.

Typical applications include repairing metallic components, such as mold tools, valves, and screws. Laser cladding is another name for the process.

LMD is replacing many traditional manufacturing processes, such as gas metal arc welding and thermal spraying.

Direct Metal Deposition

Direct metal deposition (DMD) is similar to Laser Metal Deposition, except that in DMD the powerful laser is used to create a molten pool of substrate material. Metal powder is then blown into this melt pool, where it also melts. The laser moves along to create a moving melt pool, and behind it, the molten mix solidifies. This manufacturing technique is used for the low-cost build, repair, hard facing, and reconfiguration of forging dies. This technique adds features such as flanges and bosses to forged parts, improving functionality.

DMD can be an economically viable solution. It’s also able to achieve properties that are comparable to or better than wrought material. DMD technology can be used on large parts and in production settings.

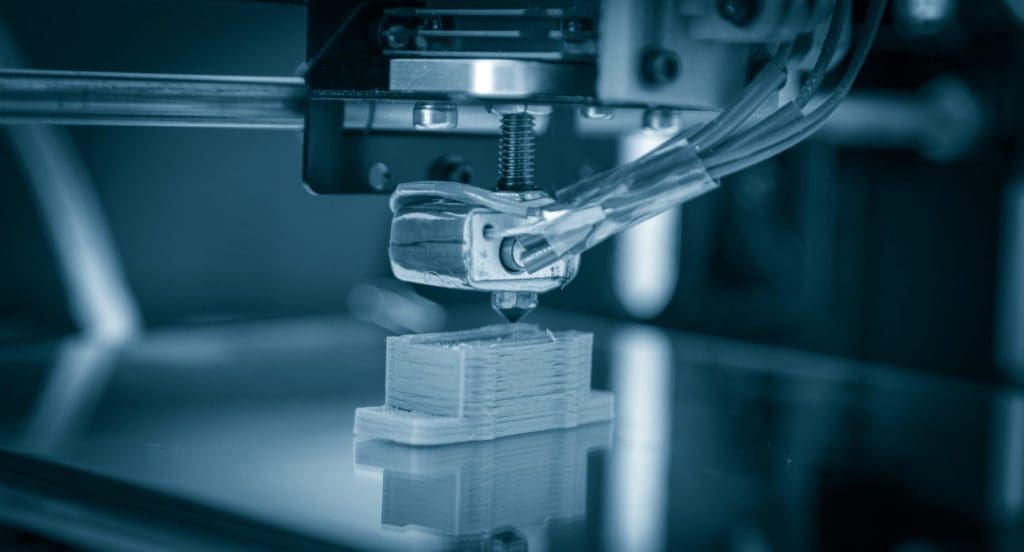

Cold Spray Metal Deposition

Cold spray technology is well established as a coating process. However, it’s also capable of being used as a form of 3D printing to build large, standalone components through metal additive manufacturing.

Cold spray differs from other metal AM approaches as there is no molten metal involved. Instead, cold spray technology uses pressurized gas to fire powdered metal particles through a nozzle with sufficient velocity to bond to the substrate upon impact.

When the metal powder particles hit the substrate’s surface, the high kinetic energy causes deformation. This deformation creates mechanical interlocking and metallurgical bonding.

There is a small amount of heat generated during this “interlocking and bonding,” but not enough to melt the metal.

The unique temperature attribute of cold spray reinforces many metals, prone to crack or deform during the rapid solidification. This solid-state process also allows printing in an open atmosphere without excessive oxidation.

Disadvantages Of Cold Spray Metal Deposition

No system is perfect, and there are disadvantages to consider with cold spray metal deposition. Some of the disadvantages include:

- Low geometric resolution.

- Low ductility in the as-sprayed condition.

Additional problems with cold spray manufacturing could include:

- the need for a ductile substrate;

- For some materials Helium is required, which adds considerable cost. ;

- Ceramics can not be deposited by themselves, only as a mix of ceramic powder and metal powder.

Advantages Of Cold Spray Metal Deposition

The advantages of the method certainly outweigh any drawbacks. Cold spray manufacturing is revolutionizing restoration and repairs, making it easy and cost-effective for welders. How is this accomplished?

Additive manufacturing using cold spray processes assist in developing parts and components rapidly. Deposition rates for cold spray metal deposition can be as high as 45 kg/hour – much faster than older additive manufacturing methods.

There are several other advantages to cold spray manufacturing, including:

- Compatibility with heat-sensitive materials.

- Low thermal stresses.

- Compressive residual stresses, which avoids “hot tearing” and cracking.

- The ability to operate in a non-inert, open environment.

- The ability to create shapes with (seemingly) no shape or size constraints.

- More efficient buy-to-fly ratio when compared to traditional machining processes.

- Extremely low toxicity for employees or team members in the area.

- The ability to recapture and reuse metal powders that don’t adhere.

- Fusing dissimilar metals to create hybrid metal parts – materials such as titanium alloys, copper, zinc, stainless steel, aluminum, nickel, even Hastelloy and Inconel can be layered together.

Unlike other heat-producing additive manufacturing methods, such as selective laser melting or electron beam additive manufacturing, the cold spraying process does not produce a high amount of heat. Thus, metal substrates are not affected by heat-related distortion. Also, parts do not need to be manufactured in inert gas or vacuum-sealed environments, allowing larger structures.

Capabilities Of VRC Cold Spray Metal Deposition

Cold spray metal deposition is a solid-state coating technology developed in the 1980s. Compared to conventional thermal spray processes, cold spray can retain the substrate material’s original properties, prevent the adverse influence on the underlying substrate materials, and produce very thin to very thick coatings, depending on the project’s need.

It is also important to note that VRC cold spray technology is compatible with virtually any metal powder.

The following materials are validated in some capacity for cold spray metal applications:

- Aluminum alloys

- Copper and copper-based alloys such as brass and bronze

- Magnesium alloys

- Nickel and nickel-based superalloys such as Inconel 625

- Precious metals

- Stainless steels

- Carbon steels

- Tin

- Titanium and titanium alloys such as Ti-6Al-4V

VRC Metal Systems researches the potential of cold spray and optimizes the process for specific applications across many industries, including shipyards, construction equipment, military vehicles, aerospace components, and more! Through our portable VRC cold spray system, we have revolutionized the process of restoration and repairs.

VRC Metal Systems and their mobile cold spray technology have made metal deposition and additive manufacturing quick, easy, and cost-effective for your team. Contact us today for training and a quote.