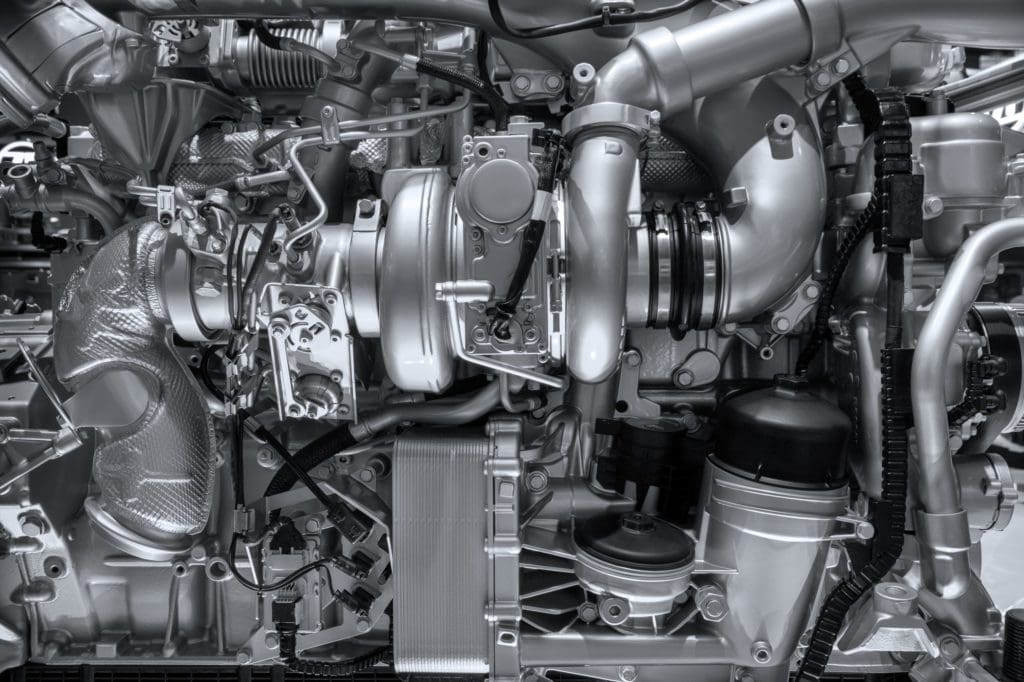

Remanufacturing an engine, being much more complex than engine repair, is a comprehensive and rigorous industrial process. Remanufacturing takes a non-functional product or component and returns it to a “like-new” or “better-than-new” condition. This industrial process improves performance level and quality. Remanufacturing is not synonymous with “recycling” or “repairing,” or even “rebuilding,” it is more thorough than any of those.

Some commonly remanufactured products are:

- Aircraft components

- Automotive parts

- Electrical and electronic equipment

- Engines and components

- Medical equipment

- Office furniture

- Printing equipment

- Restaurant and foodservice equipment

Today, let’s talk about remanufacturing engines. VRC Metal Systems and their patented VRC Cold Spray System is the ideal solution for your engine remanufacturing needs. Contact us, and we can help with affordable engine remanufacturing options.

The Case for Engine Remanufacturing

Historically, when an engine breaks down, it is often either too expensive to fix or completely unrepairable. For example, a worn area might not have enough material left to bore out or re-machine, or repair methods might be so involved that the repair cost exceeds the replacement cost. That is if you don’t have the technology to fix it!

At the same time, the Environmental Protection Agency has tightened up the emission policies for new vehicles. Manufacturers have had to change their engines for improved emission control and better efficiency, making engine replacement an increasingly costly option.

Engine Repair Options

When an engine repair is significantly needed, you face an important (and costly!) decision:

- Replace the engine with a new engine,

- Replace the engine with a used engine,

- Remanufacture the engine,

- Replace the entire machine,

- Or you can rebuild or repair the broken-down engine.

Buying a brand-new engine is usually too expensive for many budgets. The choices come down to remanufacturing the engine, a used engine (and the risks that go with it), or repairing or overhauling it.

Unfortunately, a used engine is, at best, a temporary fix. It may only buy a little more time until the next breakdown. Most used engines experience problems of their own and end up needing replacements.

So what else can you do? Let’s take a quick look.

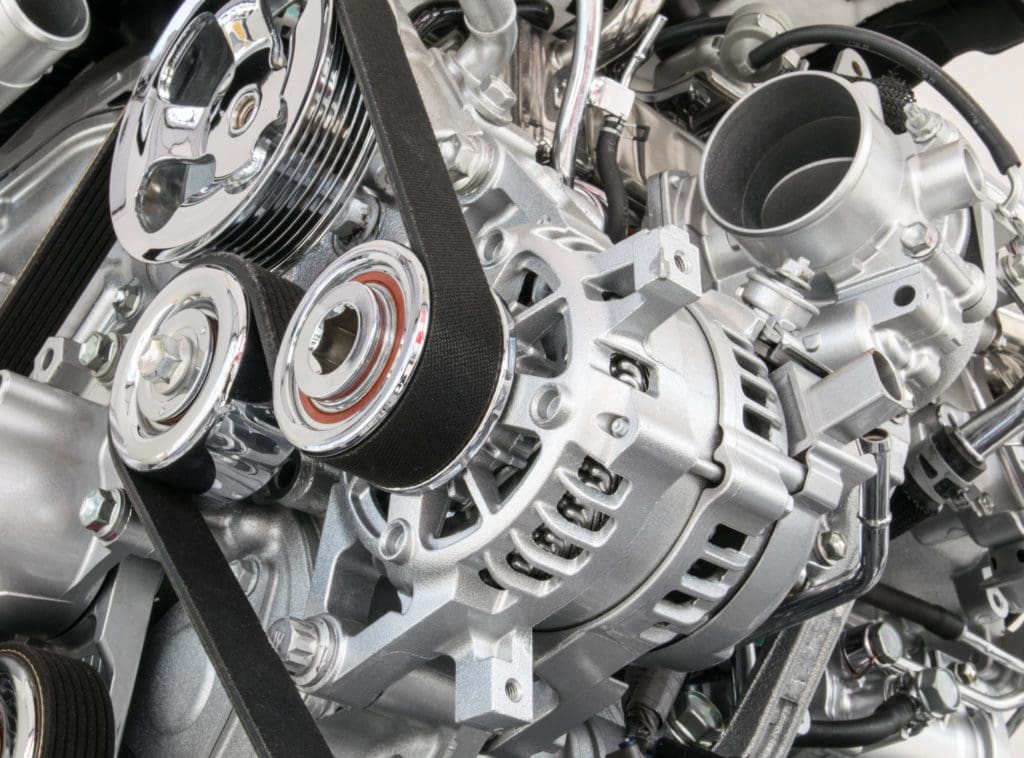

Engine Rebuilding

Yes, rebuilding an engine can cost less than replacing it.

When a technician rebuilds an engine, they take it apart and replace parts damaged, worn, or out of spec. They then reassemble the engine and test it. This is, of course, assuming the original engine is rebuildable: There is no excessive wear or severe damage. You may realize 20% to 50% (or more) in savings by rebuilding an engine versus replacing it.

Rebuilt motors work similarly to regular repairs and replacements. Instead of using new replacement parts, used parts save the customer money. There is a slight risk with rebuilt parts because all used parts show wear to some degree to be classified as “used.” While they are certified safe for use in other cars, premature failure, and additional repairs may crop up sooner than expected. Rebuilds using new parts reduce this risk but still don’t bring the engine back to “new” specification.

Engine Remanufacturing

The engine remanufacturing process is basically the engine rebuilding process times ten. Instead of rebuilding one part, the entire product has been literally remanufactured to meet “new” specifications. The engine meets or exceeds safety, durability, and quality tests.

However, with traditional techniques, remanufacturing engines can be cost-prohibitive for many companies. The complexity and cost of remanufacturing can limit options for small operations. Additive manufacturing and remanufacturing have opened the doors to a longer life-span of engines where before the doors were firmly closed.

Engine Remanufacturing Benefits the Environment, Too

Some of the benefits of remanufacturing include:

- Conservation of materials (of increasing importance as raw materials become scarcer and more expensive)

- Reduced energy consumption during manufacturing

- Especially since much less new material is needed.

- Reduced waste (and associated disposal costs)

- Lower price for a comparable quality

We can then recycle the remaining aluminum, steel, cast iron, iron, and other metals composing the non-salvageable pieces.

As a bonus, we assist OE manufacturers in reducing their environmental impact throughout each machine’s life.

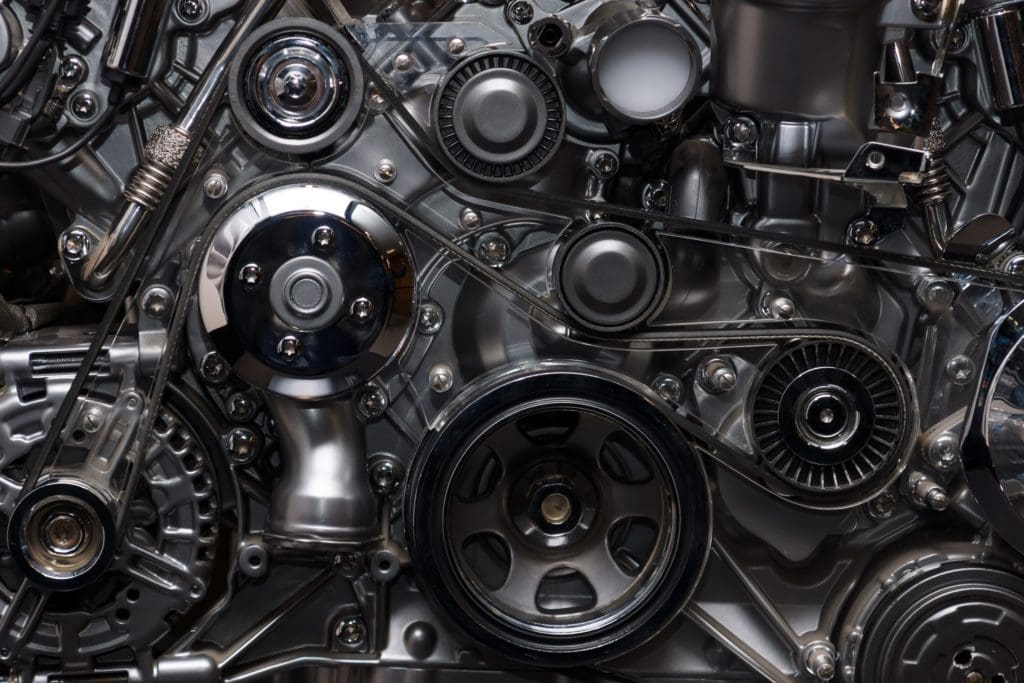

VRC Cold Spray Is the Ideal Solution For Engine Remanufacturing

Supersonic particle deposition (SPD), or cold spray, is an additive manufacturing process. SPD uses high particle velocities to create coatings that adhere extremely well, are highly consolidated, and have high strength. Cold spray uses an electrically heated high-pressure inert gas such as nitrogen or helium to accelerate the metal powders above critical velocity for particle adhesion. Ceramic particles can be mixed in to create extra hard and wear-resistant coatings.

The popularity of cold spray for metal repair is not without good reason. VRC Cold Spray is the ideal solution for engine remanufacturing.

There are many benefits to using VRC Cold Spray for engine remanufacturing and other metal repairs, including:

- No heat-affected zones. VRC Cold Spray System does not use extreme heat in the remanufacturing process and does not rely on any melting to create the coatings. This lower temperature process results in minimal oxidation, alloy decomposition, or combustion product entrapment. The base parts don’t get warped and don’t develop heat-affected zones.

- Minimal prep work is needed. Cold spray remanufacturing requires minimal cut-back of the base material.

- Improved performance. Remanufacturing through cold spray can increase the mechanical properties and fatigue life of the coating.

- Improved surface finish. Cold spray offers a high-strength, high-quality (low-defect), high-density coating that is highly machinable with conventional tools.

- Increased operator safety. Unlike other additive manufacturing processes, cold spray offers increased operational protection due to the absence of fuels, flammable gases, combustion products, and molten metal.

- Minimal masking and PPE needed. Your team won’t need lots of protective gear due to the focused particle spray path, lack of extreme heat, and lack of toxic fumes.

- Low Temperatures. Using a low-temperature process compared to other techniques has the bonus of no bulk particle or substrate melting.

- Portable. Operators can take our hand-operable cold spray system practically anywhere. Companies can replace costly and complicated procedures with a portable and innovative approach. Frequently, cold spray repairs happen without extensive engine disassembly.

- Repeat remanufacturing on an engine is possible. With our cold spray system, maintaining minimum wall thickness requirements is possible, even through multiple repair cycles, and cold spray coatings can themselves be repaired by cold spray. This allows for parts to be repaired numerous times during the engine’s product life cycle stages or base material.

- Lower time commitment. Engine blocks don’t have to be preheated for cold spray repairs, and heat input is minimal during the repair, meaning there is no long wait time for the engine block to cool. Wait time adds cost to the finished product, but trimming wait time improves your return on investment (ROI).

- Less machine rejection of repaired parts. Parts that were repaired incorrectly can be quickly reworked and brought to specification.

- High hardness, low solidification stress, and thick coatings. Reducing or eliminating solidification stresses while enabling thicker layers to be created. No limit on deposition thickness. Cold spray ensures high hardness thanks to a cold-worked microstructure.

- Savings on equipment. No need to replace whole machines when you can remanufacture the engine (or other metal parts) and get back to work!

- Savings to pass onto your customers. As raw materials and energy costs increase, remanufacturing engines can deliver more significant savings to your customers.

Engine remanufacturing using VRC’s innovative cold spray system widens the number of repairs that can be made, shortens the time for several current repairs, and allows multiple repair cycles.

Their patented VRC Cold Spray System is the ideal solution for your engine remanufacturing needs. Contact VRC Metal Systems today for more details.