Repairing or replacing equipment in your organization can be expensive and time-consuming. When a vital piece of equipment craters, the expense of repairs doesn’t stop at the machine. The Cold Spray Coating Process can reduce or eliminate downtime, and provide several other benefits to companies that make and fix products.

VRC Metal Systems partners with you to deliver customized cold spray coating process solutions to keep your operation running smoothly and reliably.

Contact us today to discuss your needs and find out how cold spray technology can be a top asset in your company.

Recent but reliable

The cold spray coating process was first discovered in the mid-1980s at the Russian Academy of Sciences, but it wasn’t until the late-1990s that it was first patented in the U.S. and began to pique the interest of national labs, aerospace companies and the Department of Defense. Now, after more than two decades of research and development, cold spray is solving real-world problems most people never dreamed would be possible.

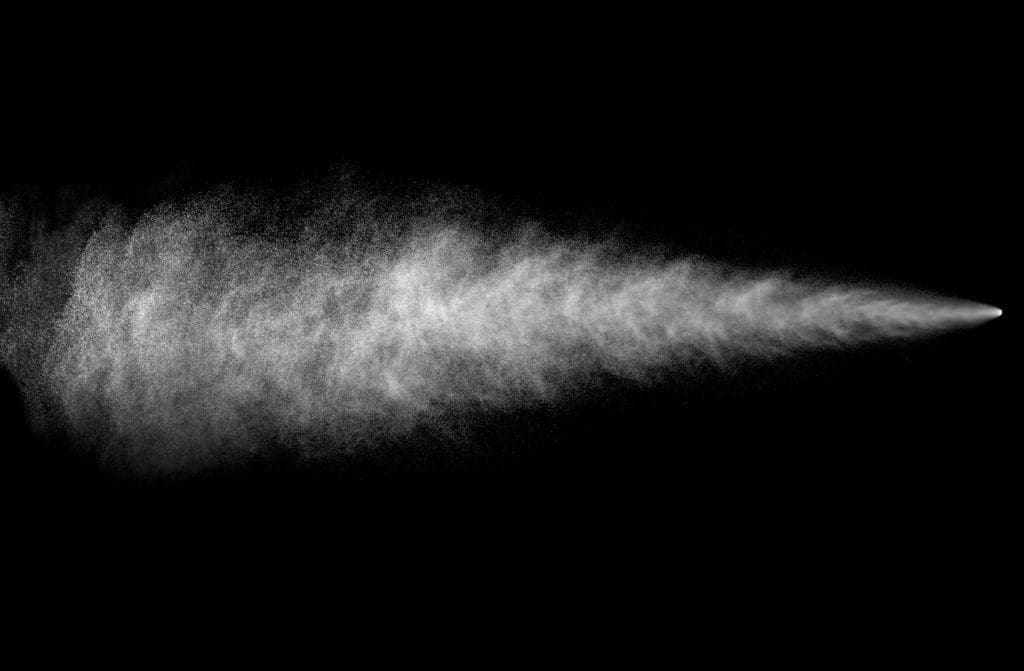

The cold spray coating process combines coating particles with high-pressure gas and accelerates them to supersonic speeds through a nozzle and onto a surface. The coating particles bond to the desired surface without the chemical and molecular changes that accompany other high-temperature spray applications.

In short, the cold spray coating process presents several advantages for equipment repair. With cold spray technology, you can prolong equipment life, reduce downtime, save money on new equipment purchases, and reduce labor costs attached to equipment repair.

A detailed look at how to use the cold spray coating process to your advantage

Unlike high-temp bonding applications, the cold spray coating process does not remarkably change the base materials that are coated. During the coating process, all materials remain in a solid-state, as opposed to the physical changes that can occur with high heat, like melting and phase transformation.

As a result, the sprayed metal particles experience reduced oxidation, and surface oxides are literally blasted away by the impacting particles, which assists the bonding process. Further, the bonded section does not shrink after the application from solidification, as materials do during other high-temp thermal spray and weld coating processes.

Because of the extremely high pressure applied to the spray coating and the velocity they achieve upon exiting the supersonic nozzle, the sprayed particles bond as if they were Play-Doh thrown at the substrate surface.

Think of the cold spray coating process like tiny particles of sprayed coating essentially “hugging” tightly the particles on the substrate surface. A molecular embrace like the one described is difficult to break. It’s essentially a mixture of metallurgical and mechanical bonding, that is so good, the coating is often indistinguishable from the substrate.

Cold spray particles exit the “gun” in a narrow “beam.” This precision affords greater accuracy in the coating application and offers more coating thickness options and shape control than thermal spray methods.

The best materials for spray coating and substrates

Coatings:

- Titanium

- Copper

- Stainless Steel

- Aluminum

- Alloys of the above materials

- Ceramics (must be applied as a composite, not in pure form.)

The best surfaces for cold spray bonding include any surface that can withstand the high-pressure cold spray coating process. Soft substrates would likely erode under the pressure-sprayed particulates. The same is true for friable surfaces.

Industrial relevance

To date, the cold spray coating process is commonly used in:

- The aerospace industry (for example, in aluminum coatings to refurbish or protect magnesium components)

- Heavy Industrial shafts and cast-iron engine casings

- Nuclear fuel rod coatings and component repairs

- The cookware industry (ferrite coatings on certain conduction cookware pieces)

- Near net shapes, performance-enhancing layers, free forms

- Turbine component coatings

- And many more we just can’t talk about…

The industrial applications for cold spray evolve continually with technology advancements and capabilities

The cold spray coating process advantage

Above, we discussed the physics and structure of cold spray bonds, which can preserve the metal composition and bond size of the spray particles and the substrate surface. There are several other advantages of using cold spray technology.

- Cold spray is portable: This technology may reduce or eliminate the need to pull machinery off a production line or disassemble equipment to access the surface to be fixed or coated. Cold spray guns are agile and can fit into a variety of spaces while applying reliable bonds and coatings of precise thickness.

- Cold spray is fast: Because this technology eliminates several steps from a conventional high-temp bonding process, repairs occur in a fraction of the time. There’s no need for “cooling” from a hot bonding application. You can often achieve a “shoot-and-start-up” result from a cold-spray bond.

- No bulk particle melting: Because of the high-pressure bond created by cold spray, melted particles are not necessary for the process.

- Enables thicker coatings: Because of the elimination of solidification stress (stress or deformation on the substrate surface as it hardens after high-temp bonding), you’re clear to thicken the coating dramatically, at a lower risk.

- Decreased surface prep: The cold spray coating process often reduces the need for grit blast on the substrate surface. Because of the narrow particulate stream, you may also reduce or eliminate masking on the substrate surface.

Other cold spray coating process advantages

Since cold spray technology does not compromise either the particle or substrate structure during the bonding process (remember the molecular “hug” we talked about earlier?), bonds, coatings, and repairs may last longer than in welding or other thermal spray applications.

When your equipment lasts longer, you save money in the long run with reduced capital expenditures on machinery. Furthermore, your production line or other services can enjoy more “up” time over the life of your equipment.

Both of these scenarios mean more revenue potential with fewer operation interruptions.

With the agility of a cold spray system, you may also save significantly on labor costs in your shop. Your maintenance staff can pinpoint the part or machine in need of repair or coating, and shoot a coating onto the desired seam, joint, or part with increased dexterity and speed.

VRC Metal Systems knows cold spray technology

With services ranging from on-site equipment training to sourcing additives to equipment leasing, VRC Metal Systems is an end-to-end partner in developing your cold spray solutions.

Our customized approach means we strategize, source, and develop the right equipment, tools, and materials to meet your coating needs. We also stay on the leading edge of cold spray technology innovations and remain able to solution-find on demand for our clients.

Contact us today to set up a cold spray technology consultation, and see in real-time how you can benefit from using the cold spray coating process in your operation.