Category: Cold Spray

-

Introducing the Dragonfly™ Cold Spray System

When metal repairs must be performed swiftly in environments where large machinery may not be feasible, a reliable and portable solution is essential. VRC Metal Systems introduces the Dragonfly™ Cold Spray System—a cold spray solution meticulously designed for in-field repairs. This system eliminates the necessity of removing metal components that require off-site repairs, resulting in…

-

Enhanced Aircraft Sheet Metal Construction and Repair

In aerospace, MRO (maintenance, repair, and overhaul) is expensive and time-consuming for the commercial aerospace industry, but there are new ways to reduce repair costs and downtime while maintaining safety and durability. VRC Metal Systems’ high-pressure cold spray adds fresh, solid metal without melting anything. It can be used to repair and enhance parts, decreasing…

-

How Mobile Cold Spray Repair Can Help Shipyards Save Money

Thousands of ships continually sail the oceans to move people and goods. Just like any other machine a ship requires frequent maintenance and repairs. Every two years or so, ships dock in your shipyard for assessment and repair. A unique challenge that other means of transport don’t face is the sheer corrosiveness of the ocean.…

-

Overview of On-site Installation and Integration of VRC Metal Systems

VRC Metal Systems is the leader in high-pressure cold spray technology. We serve several sectors, including aerospace, defense, energy, and the transport sector. Our cold spray systems are used as part of the heavy equipment engine remanufacturing process, and we support and perform shipyard repairs. Do you think you could benefit from cold spray coating…

-

How to Choose the Best Corrosion Resistant Coating

The best corrosion resistant coating will protect against surface damage while standing the test of time. Corrosion resistant coatings need to prove strong against fatigue and environmental stressors. VRC Metal Systems is committed to helping you find the best solution to fight against surface corrosion. A variety of common environmental stressors cause corrosion: A humid…

-

3 Benefits of Cold Spray for Military Vehicle Repair

Military vehicles are under constant attack from an unexpected enemy – corrosion. Corrosion damage to military ground vehicles cost the US Army 1.2 billion dollars in 2016 alone. There is a huge cost to keeping military vehicles in ready repair. When considering how cold spray might help military vehicle repair, you can easily point out…

-

7 Ways Cold Spray Is Reshaping Repair Strategies In Manufacturing

Equipment breakdowns in your organization can lead to costly repair or replacement along with extended downtime that eats into your revenue. Cold spray coatings are reshaping repairs to reduce or eliminate downtime and provide several other benefits to companies. VRC’s Cold Spray System delivers customized cold spray coating process solutions to keep your equipment running…

-

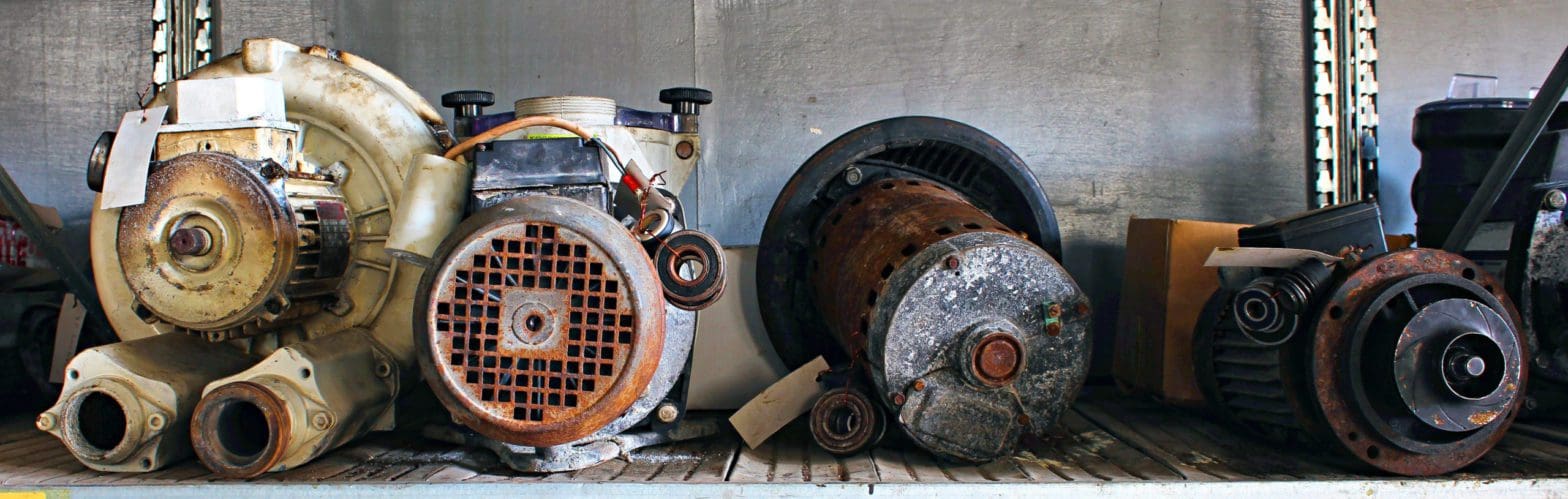

Cold Spray Less Cumbersome For Large Equipment Repairs

Large, heavy-duty equipment is a significant investment for many companies. When a large machine is out-of-order it is not generating revenue so repairs need to happen quickly without delays or further injury to the equipment. Repairs should consider a few things, including the materials required, the parts needing work, and the reliability of the repair.

-

Use Copper to Microbe-proof Your Medical and Restaurant Equipment

Table of Contents With the medical and food production industries coming under unprecedented pressure for cleanliness and sterilization in the age of COVID-19, ensuring the safety of production lines and supplies is paramount. Cold spray coating equipment can provide self-sanitizing coatings for a safer manufacturing solution in these unprecedented times. As a cold spray technology…