Category: Blog Post

-

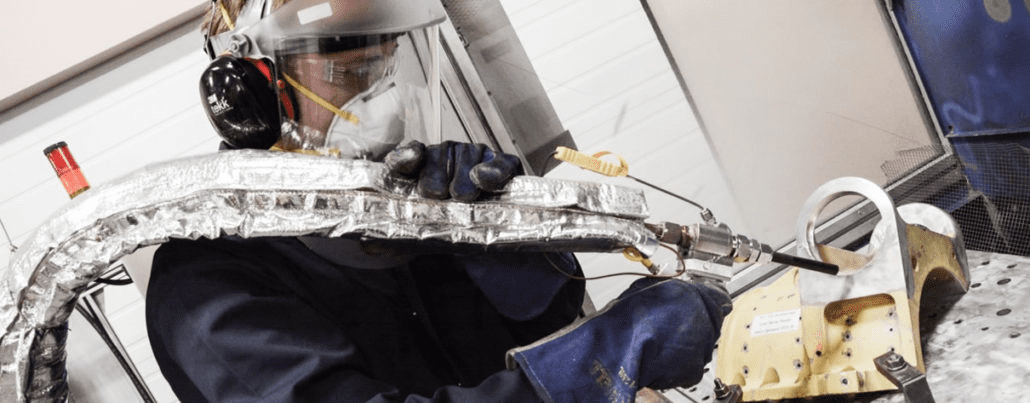

Introducing the Dragonfly™ Cold Spray System

When metal repairs must be performed swiftly in environments where large machinery may not be feasible, a reliable and portable solution is essential. VRC Metal Systems introduces the Dragonfly™ Cold Spray System—a cold spray solution meticulously designed for in-field repairs. This system eliminates the necessity of removing metal components that require off-site repairs, resulting in…

-

VRC Metal Systems Receives Lockheed Martin Small Business Award

Box Elder, SD (July 1st, 2023) – VRC Metal Systems, a leading developer of advanced cold spray technologies, announced that it has been awarded the prestigious Lockheed Martin Missiles and Fire Control Exceptional Small Business Award. The Lockheed Martin Missiles and Fire Control Exceptional Small Business Award is presented annually by Lockheed Martin and showcases…

-

Introducing The C.A.M.P. Site™ System

View Full Video For Entire Walk-Around Of The C.A.M.P Site™ System Introducing the VRC Metal Systems C.A.M.P Site™ Cold Spray System. C.A.M.P Site™ stands for Cold Spray Advanced Manufacturing Portable Site which means this containerized unit is our most powerful and relatively portable unit to date. The C.A.M.P Site™ system is designed to be self-supporting…

-

What Are Antifouling Hull Coatings?

Fouling is the deposition and accumulation of unwanted material on surfaces exposed to fluids. These unwanted deposits can include scale, insoluble salts, proteins, bacteria, algae, zebra mussels, and other aquatic organisms. Fouling is an issue, not only for marine vessels but also for heat exchangers, cooling towers, piping, or any industrial equipment subject to stagnant…